Manufacturer and Designer of Quality magnets since 1921

INDUSTRIAL MAGNETIC SYSTEMS PRODUCT LINE

3 magnetic technologies - Advatages vs Disadvatages

| Magnetic Technology | Advantages | Disadvantages |

|---|---|---|

| Electromagnetic | Strong and deep magnetic field, adjustable magnetic force with use of a potentiometer, easy to turn on and off, great option for junk yard magnets and certain surface grinding applications | High power consumption, requires a constant power source, can generate heat during use, potential for electromagnetic interference |

| Electropermanent | Strong and powerful holding force, does not require a continuous electrical source, does not generate heat, adjustable magnetic force via remote control, easy to turn on and off, great option for all workholding and many lifting applications | Can be more expensive than some electromagnetic systems and regular permanent magnets |

| Permanent | No power source required, lower cost, low maintenance, no risk of electromagnetic interference, long-lasting magnetic force | Fixed magnetic force, may not be strong enough for some applications, may not be suitable for all workpiece shapes and sizes, difficult to turn on and off |

Keep in mind that the suitability of each magnetic technology will depend on the specific application and requirements of the magnetic chuck or lifting magnet. Speak to a Braillon representative today for more details.

DOWNLOAD OUR PDF CATALOG

industries we serve

Tool and Die / Mold Making

Steel Manufacturing & Processing

Mining & Recycling

Automotive & Aerospace

Rail Manufacturing

We have 100 years of

experience in this field

Since 1921, Braillon Magnetics, has been a magnet manufacturer and innovator of magnetic systems for the industry. It all started with a small job shop located in the French Alps. Today, we have representation all around the globe, including Chicago Illinois.

great technicians

Quality Engineering

COMPETITIVE PRICING

Years Experience

Great Services AND PRODUCTS

Technical Repairs

We offer testing and repair services for Magnetic chucks, Lifting Magnets, Control units, and more...

CONTROL UNITS

Replace or upgrade any control unit for your magnetic chucks or lifting magnets. 110V to 480V options.

Installations

Contact us to assist with the install of your new or used magnetic chucks and lifting magnets.

Why choose Us

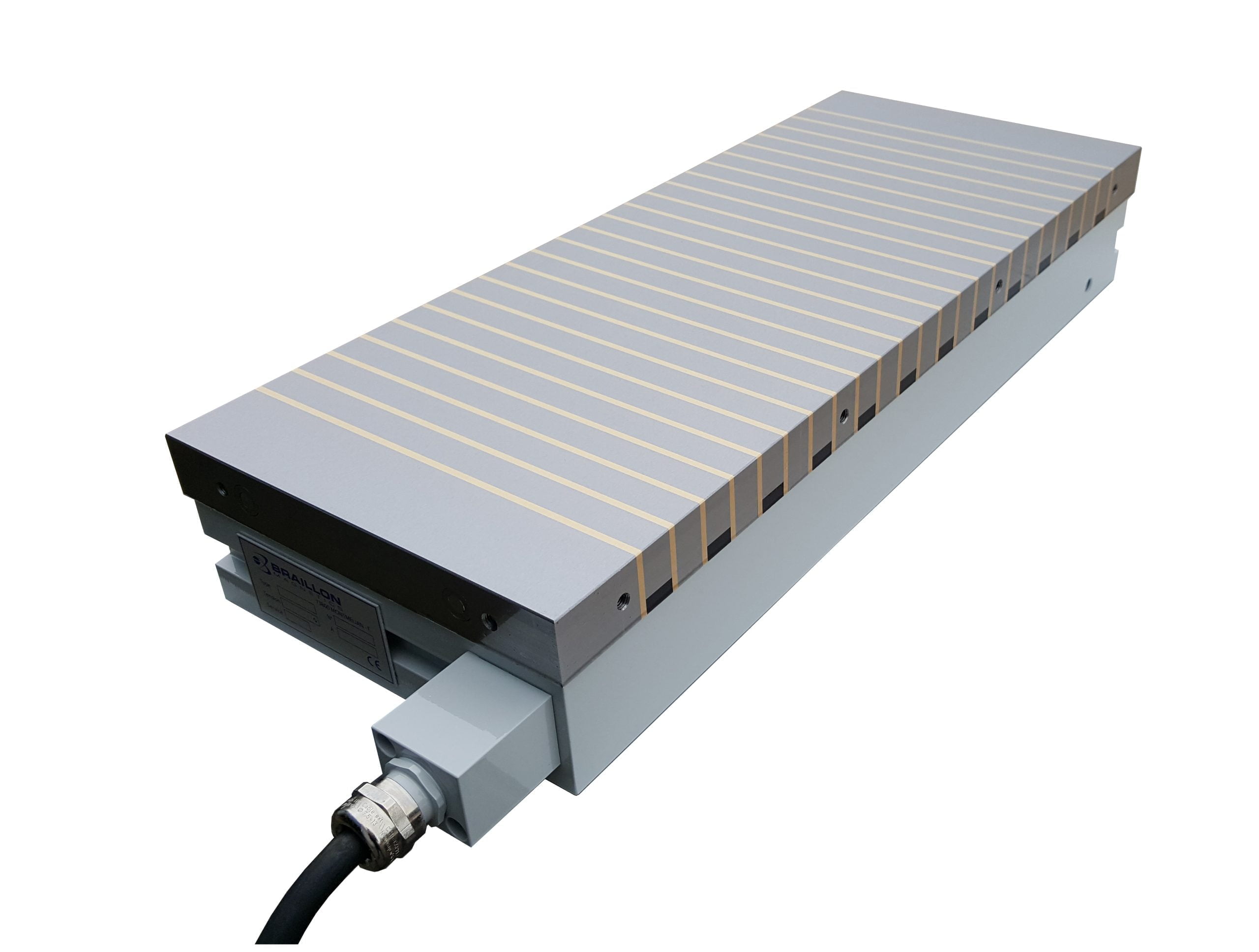

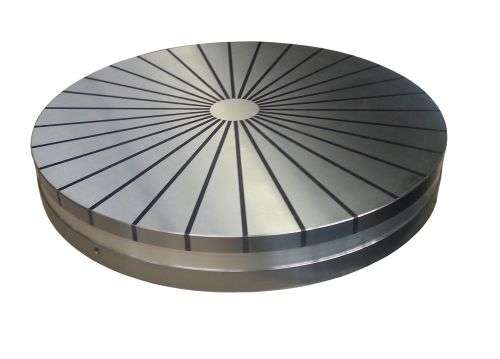

CUSTOM & StANDARD APPLICATIONS

Of course, we have off-the-shelf products for your magnetic lifting needs and magnetic workholding. But where we really shine is our custom applications. Not all magnets will fit your specific application needs. So, we make it our business to make sure you have the right magnet for the job at hand. From automation to 5 axis machining, we have you covered. We will customize our products for you.

- PERMANENT

- ELECTROMAGNETIC

- ELECTRO-PERMANENT

- DEMAGNETIZERS

- EDDY CURRENTS

- AUTOMATION

HOW can we help

Reach out to us today. We would love to hear from you and any projects you may have. We are here to help. We have dedicated engineers that can assist you in making the right decision for your magnetic applications. Workholding, Lifting Magnets, Demagnetizers, Quick Mold Change Systems, and more…

CONTACT CHICAGO Office

- 1-(312) 912 1355

- usa@braillon.com

-

Braillon Magnetic Systems Inc.

2333 Wisconsin Ave.

Downers Grove IL, 60515