MAGNETIC CHUCKS FOR MILLING - TOP 2 TECHNOLOGIES

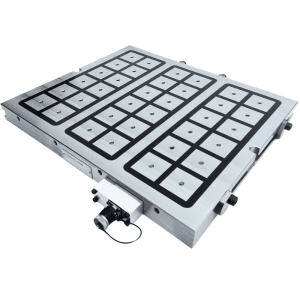

ELECTRO-PERMANENT MAGNETIC MILLING CHUCKS

Electropermanent magnet milling chucks are a great options that for 5 axis machining. They last many years, great ROI. There is no moving parts inside these chuck. Power is only needed when turning the magnet on or off

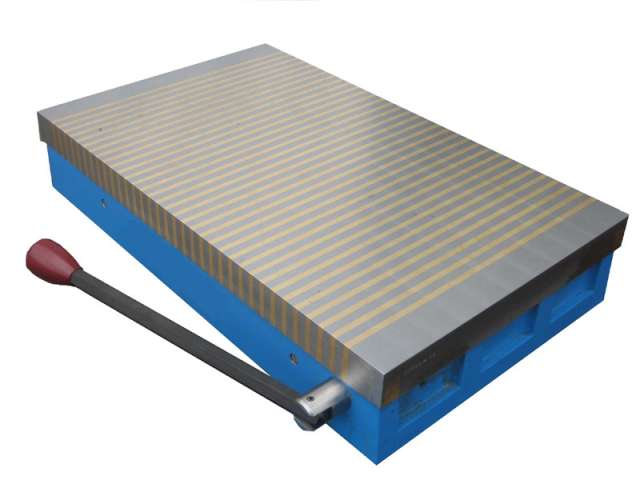

PERMANENT MAGNETIC MILLING CHUCKS

Permanent milling chucks are an excellent option for customers seeking an option that is not electrical. These milling magnets are usually turned on and off mechanically with a lever or Allen key. Zero reliance on electricity for this type of mag chuck.

machine all 5 sides with our chucks

Electro-Permanent or Permanent magnetic chucks for milling can both be great options if you work with a 5 axis cnc mill. You don't have to worry about any wires or cables being attached to the magnet during your manufacturing process. Face mill without a hitch. Screw on some raiser blocks and you can edge mill all sides. Get machining and even drilling through parts today!

Electropermanent Technology since 1963

In 1963, Braillon Magnetics pioneered the revolutionary Electropermanent (EP) Magnetic Chuck, marking the inception of a technology that has continually evolved. Today, our EP technology boasts a remarkable range of robust and reliable magnetic chucks.

The TURBOMILL (TM SERIES) magnetic chucks are crafted from a single, ultra-resistant steel block. These chucks offer unparalleled rigidity and exceptional magnetic efficiency. The result is a stable chuck geometry, an extended lifespan, and a fully waterproof construction. Through relentless research, employing the latest generations of powerful magnets, and advancing our Electro-Permanent magnetic circuits, Braillon Magnetics can handle even the most demanding milling applications.

The outcome? A remarkable increase in productivity, making your milling processes more efficient than ever before.

PERMANENT MILLING MAGNETIC CHUCKS

ELECTRO-PERMANENT MILLING MAGNETIC CHUCKS

TYPE TM50 SQ3

This electro-permanent chuck has robust stainless steel airgaps. It can withstand a long term beating in the shop. A great 5 year warranty comes with this milling chuck.

TYPE TM40

The TM40 is the best magnetic chuck for plate milling. Extremely robust body and poles. Completely water proof. This electro-permanent chuck will last years and years to come. 40mm pole pitch!

TYPE TM18

Similar concept to the TM40. This Electro-Permanent magnetic chuck has an 18mm pole pitch . Great for milling medium to small sized parts. Add some pole risers made of mild steel and customize your nesting.

TYPE TM50 SQ1

Similar to the TM50SQ3, this milling chuck also has a 50x50mm square pole airgap. The airgap to this magnetic chuck is made of a high impact resistant resin epoxy. A great standard option.

CHECK OUT SOME OF OUR SHOP DIRECT DIRECT OPTIONS

$3,200.00 – $4,800.00

$3,200.00 – $4,800.00- Select options This product has multiple variants. The options may be chosen on the product page

How they work

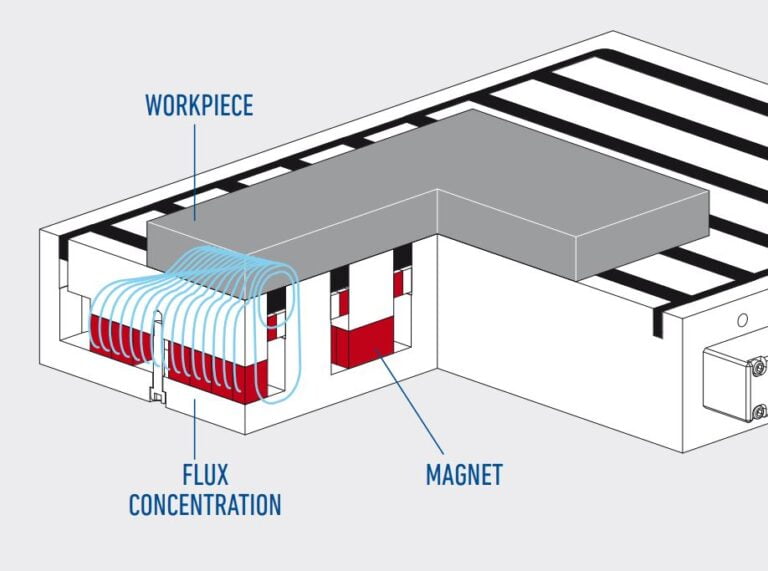

Parallel poles allow for great flux concentration

The parallel pole system stands out from other

electropermanent systems by its unique design that

promotes the concentration of the magnetic flux.It allows to reach forces of attraction particularly high,

which can go beyond 242 pounds per square inch (17kg/cm2).

.

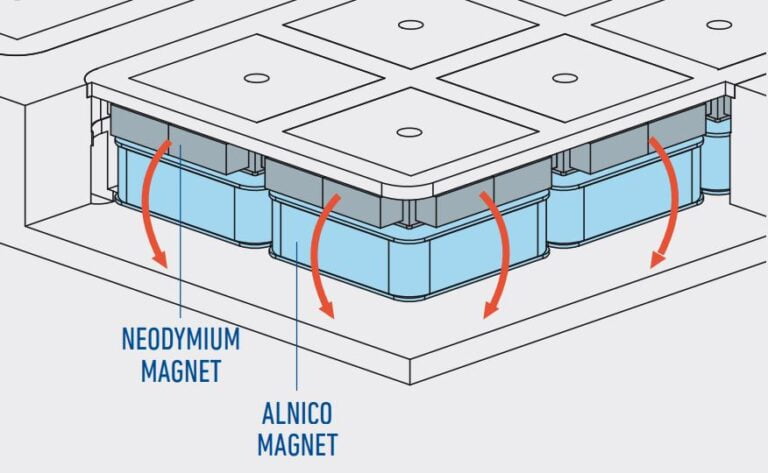

Magnetized vs. Demagnetized state

They are most often used as a magnetic workholding device and installed on a mill or surface grinder. A permanent magnetic chuck is simply activated and deactivated mechanically. The permanent magnets (usually rare earth, Alnico or ferrite) are always active inside the chuck. The magnetic field stays locked inside the chuck when it is not activated.

When activated, the magnetic field is released and now able to lock into the part that is to be surface ground or milled.

Unlike other types of workholding devices that require clamping, a permanent magnetic chuck provides a secure hold without the need for mechanical clamps or fixtures, allowing for faster and more efficient machining operations. Permanent magnetic chucks are commonly used in grinding, milling, and drilling applications.

An electro-permanent magnet for milling is a type of workholding device used in milling operations to hold ferromagnetic workpieces securely in place during the manufacturing process. It has the advantage a permanent chuck that does not rely on constant electricity to hold parts. Which means greater safety for the operator and you save on your electric bill! It has no moving parts, which means a very slow wear and tear. Since there is no constant electricity going through a coil, it provides the advantage of working with a cold surface and avoiding heat and the potential deformation to the steel part, a great advantage vs. an electromagnet.

A magnetic chuck for milling machine can be easily installed on most 5 axis CNC machines and:

Column Milling Machines.

Turret Milling Machines.

C-Frame Milling Machines.

Horizontal Milling Machines.

Tracer-Controlled Milling Machines.

Bed-Type Milling Machines.

Planer-Style Milling Machines.

Gantry Milling Machines.