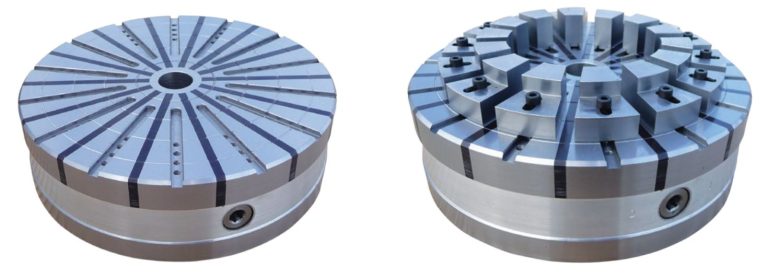

Rotary Magnetic chuck for cylindrical grinding & TURNING

The ERCA is a permanent circular magnetic chuck with radial poles. This magnetic lathe chuck is made for the true professional. The best round magnetic chuck that uses Alnico permanent magnets. Designed with the precision customer in mind. Perfect for your rotary grinding machine or use as a lathe magnet. ID/OD applications;

- PRECISION GRINDING

- CYLINDRICAL GRINDING

- TURNING

- HARD TURNING

- MEASURING

Product Details

- T-slots in each pole

- Through hole in the middle

- Raiser pole shoes

- Auxiliary top plate

- Fitting adaptors

- Morse cone 3 or 4

- Short taper flanges

REF# 11.01.ERCA

SEE MORE Circular CHUCKS

Lift magnets for you

The great part about the ERCA is that is that there is no need for electricity. It is made with the highest quality Alnico. Using Alnico magnets allows the user to softly and precisely decide how much magnetic force he wants to release from the magnetic chuck. Use an allan key to activate or deactivate the rotary magnetic chuck ERCA. Unlike a similar magnet that would use rare earth magnets and not allow for that kind of precision handling. Since there is no coils and electricity running through it, this chuck stays cool and does not distort your part through heat.

Most commonly used on a lathe for the purpose of cylindrical grinding or ID/OD turning. It can also be used for other workholding applications that need to hold a ring or cylindrical shaped parts. If you are unsure if this magnetic chuck will do the trick, the call Braillon USA to get some help.

Permanent chucks are a type of workholding device that use magnets to hold ferromagnetic materials securely in place during machining.

They are used to hold and secure round or cylindrical workpieces, allowing for easy rotation during machining operations. These chucks typically have a circular shape and are made from a permanent magnet material such as neodymium or ferrite.

One of the main advantages of using permanent magnetic chucks is their ability to hold workpieces securely without the need for clamping or fixturing. This can save time and improve efficiency in the machining process. Additionally, because there are no clamps or fixtures to interfere with the machining process, there is less risk of distortion or damage to the workpiece.

Another advantage of using permanent magnetic chucks is their ability to provide consistent and uniform holding force across the entire surface of the workpiece. This can help to ensure that the workpiece remains stable and does not move or shift during machining operations.

When selecting a round magnetic chuck, it is important to consider factors such as the size and shape of the workpiece, the weight of the workpiece, and the type of machining operation being performed. Additionally, it is important to ensure that the chuck is properly maintained and cleaned to prevent damage to the magnet and ensure optimal performance.

In conclusion, permanent magnetic chucks, particularly round magnetic chucks, are a versatile and effective workholding solution for rotary grinding, turning, and grinding applications. They provide secure and consistent holding force, and can help to improve efficiency and precision in the machining process.