Magnetic chuck - A comprehensive guide

Table of Contents

We searched the internet high an low to find a comprehensive guide on magnetic chucks. There was a lot of information, however there was no site that gathered all the information concerning magnetic workholding. So, to help users find all the details they need on this subject, we created the perfect comprehensive guide to fill that void on the web!

What is a magnetic chuck?

It is is a type of workholding device that uses a magnetic field to securely hold a workpiece in place during machining or other manufacturing operations. It is commonly used in metalworking applications such as milling, grinding, EDM and drilling.

A typical mag chuck consists of a top plate made of an airgap (brass, non magnetic stainless or resin) and a mild steel. The workpiece is placed on it. A magnetic field is created inside the chuck by magnetic material such as Neofynium or Alnico magnets. The field can also be created by electromagnetism. The strength of the magnetic field can be adjusted by using a control unit or rectifier with a remote control.

3 main technologies

Permanent Magnetic Chuck

Permanent magnetic chucks use permanent magnets to hold workpieces in place. They are typically the most affordable type and they are mechanically activated.

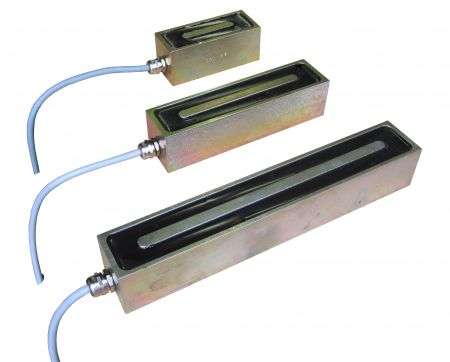

Electromagnetic Chuck

Electromagnetic chucks are made with only coils. You will not find any magnetic material in a electromagnetic chuck. The Coils will produce the magnetic field.

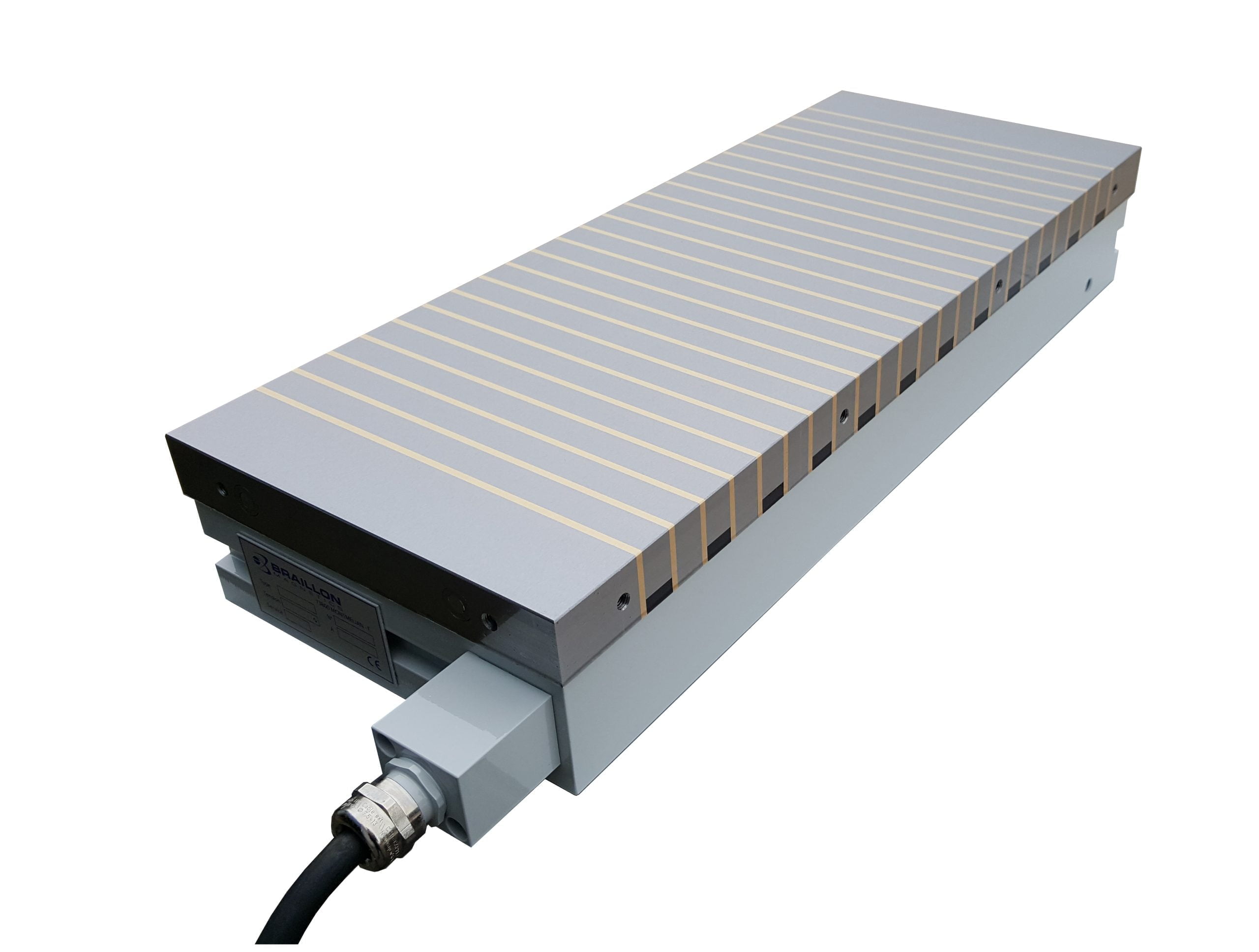

ELECTROPERMANENT MAGNETIC CHUCK

Electropermanent magnetic chucks use a little bit of both technologies. You will find real permanent magnets (usually rare earth or Alnico magnets) wrapped in coils.

| Type | Features | Benefits | Drawbacks |

|---|---|---|---|

| Permanent | Mechanically activated | No electrical power needed, most affordable | Sizes are limited, wear and tear of internal magnets |

| Electropermanent | Safety even in the event of power loss | Electrical power is only needed a few seconds during the mag and demag cycles | Can be the more costly option |

| Electromagnetic | Deep magnetic field that is best for junkyard magnets | Only coils are needed to make them, no rare earths or alnicos | The coils produce a lot of heat that can be bad for precision grinding applications |

Benefits to using magnetic workholding

There are many benefits to using a magnetic chuck, including:

- They are fast and easy to use.

- Access to all 5 sides of the part in one setup. Great for CNC Mills with swivels.

- They are very precise and can hold workpieces in place with a high degree of accuracy.

- Reduced vibration compared to mechanical workholding.

- They are durable and can withstand a lot of wear and tear.

What is a magnetic pole pitch?

A pole pitch refers to the distance between two adjacent magnetic poles on a chuck. It is typically measured in millimeters or inches, and it is an important characteristic of a magnet as it can help determine the magnetic field strength, height and distribution.

In a cylindrical magnet, the pole pitch is often calculated by dividing the circumference of the magnet by the number of poles. For example, a magnet with a circumference of 100mm and four poles would have a pole pitch of 25mm.

A fine pole pitch will keep the magnetic field low, great option for holding thin or small parts.

The larger the pole pitch is, the higher the magnetic field. So in contrast, a large pole pitch is perfect for thick or large blocks of steel.

Surface Grinding CHUCK Pole pitch EXAMPLES

MILLING CHUCK Pole pitch EXAMPLES

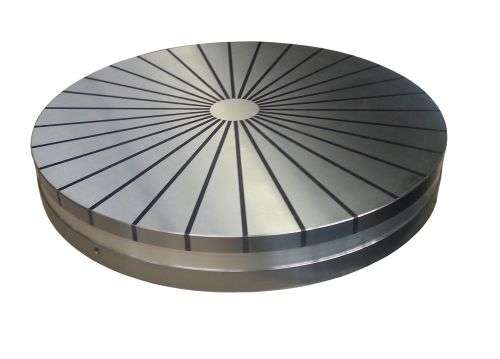

Circular CHUCK Pole pitch EXAMPLES

4 Magnetic Pole pitch styles

Proper maintenance

A. Cleaning the surface of the magnetic chuck

B. Proper storage and handling

C. Inspection and replacement of worn components

D. Avoiding exposure to extreme temperatures or strong magnetic fields

Conclusion

A magnetic chuck can come in many forms, shapes and Sizes and technologies. Used throughout the world for many manufacturing processes. Allowing countless industries to work more efficiently through faster setup times on their machines.

It is important yo keep proper maintenance of a magnetic chuck. This will allow it to keep working for many more years to come.

Call Braillon Magnetic Systems Inc. today and speak with us concerning your application or if you are looking for magnetic chuck for sale.

If you are a European based customer, please go through www.braillon.com directly.

FAQ

A magnetic chuck is a device that uses strong magnetic fields to securely hold and position ferromagnetic objects for machining, grinding, and other precision operations on metalwork. The purpose of a magnetic chuck is to eliminate the need for clamping devices and minimize setup time, allowing operators to quickly change setups and workpieces. In addition, a magnetic chuck ensures high precision in workpiece positioning, enhances stability and supports smooth operations, and reduces wastage, helping to achieve a better surface finish. Some applications of magnetic chucks include metalworking, mold making, and engineering, among others. Overall, the purpose of a magnetic chuck is to provide a reliable and efficient solution to holding workpieces in place during machining applications.

The strength of a magnetic chuck depends on various factors, such as the size, shape, and material of the workpiece, as well as the strength and type of the magnetic force used by the chuck. Generally, magnetic chucks are designed to provide a strong and reliable grip on ferromagnetic materials, such as iron, steel, and other alloys. Depending on the application requirements, magnetic chucks can provide holding forces ranging from a few pounds to several tons.

The exact strength of a magnetic chuck can also depend on the condition of the chuck, such as its age, wear and tear, and maintenance. To ensure optimal performance, users should follow the manufacturer’s guidelines for installation, maintenance, and operation of the magnetic chuck. It is also essential to ensure proper grounding and safety measures are in place to prevent accidents and equipment damage.

No, you should not drill into a magnetic chuck unless you have the ” all clear” from the manufacturer. Magnetic chucks are designed to hold magnetic materials securely in place during machining processes. Drilling into a magnetic chuck can damage the magnetic surface, the magnets or coils, and the magnetic field, compromising its ability to hold materials securely. This can lead to inaccuracies in the machining process and potentially hazardous working conditions. If you need to drill holes into the workpiece mounted on the magnetic chuck, it is recommended to remove the chuck from the machine table and use a separate drill press. If you need to drill through a part on the chuck, make sure you use riser blocks.