Permanent magnets - what are they?

A permanent magnet is a type of magnet that retains its magnetic properties without the need for an external power source. It produces a magnetic field continuously and does not require any additional electrical current to maintain its magnetism. Permanent magnets are made from materials that possess intrinsic magnetic properties, such as iron, cobalt, nickel, and certain types of rare-earth metals like neodymium and samarium-cobalt.

Permanent magnets have several characteristics:

1. Magnetic Field: They generate a magnetic field that attracts ferromagnetic materials like iron, nickel, and cobalt.

2. Retention of Magnetism: Once magnetized, a permanent magnet retains its magnetic field unless demagnetized by external factors such as high temperatures or strong opposing magnetic fields.

3. Stability: They provide a stable and reliable source of magnetic force without the need for power supply or maintenance.

Permanent magnets have various applications in everyday life and various industries. Some common uses include electric motors, generators, speakers, magnetic separators, MRI machines, magnetic toys, and magnetic workholding and lifting devices made by manufacturers such as Braillon Magnetics.

4 types permanent magnets

Samarium Cobalt

Samarium Cobalt magnets are made of a combination of samarium, cobalt, and iron. They have high magnetic strength, thermal stability, and can operate at high temperatures. Due to their resilience, they are used in industrial motors, sensors, and generators.

Neodymium

Neodymium magnets are made of alloy containing neodymium, iron, and boron. They are the strongest type of permanent magnet and are used in various electronic devices, including headphones, speakers, and hard disk drives.

FERRITE

Ferrite magnets are made of ceramic materials, mainly iron oxide. They are affordable and widely used in motors, speakers, refrigerator magnets, and even toys. They have lower magnetic strength compared to other magnets but make up for it by being cost-effective and easily available.

ALNICO

Alnico magnets are made of a combination of aluminum, nickel, and cobalt. These magnets have excellent durability and retain their magnetic strength even under high temperatures. They are commonly used in sensors, mechanical instruments, and loudspeakers.

INDUSTRIAL MAGNETIC USE

Braillon Magnetics has been using permanent magnets to construct industrial magnetic tools that help the world of manufacturing. Products that Braillon Manufactures with Alnico, Ferrite and Neodymium include: Custom permanent magnets, Permanent Lifting magnets, Permanent magnetic chucks for milling, surface grinding, EDM, ID/OD grinding and turning.

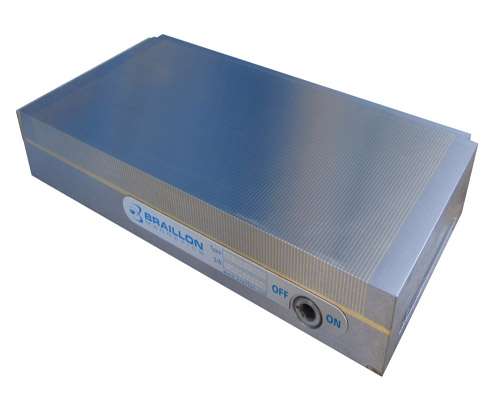

Surface Grinding magnetIC CHUCK

These Mechanically activated magnetic chucks are Available in FERRITE, Nodymium, Alnico options.

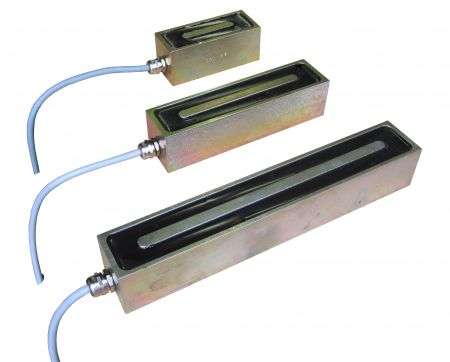

PERMANENT Lifting Magnets

Lifting Magnets used to be made with Ferrite or Alnico, however they are most often now made with rare earth Neodymium

Permanent ChUCK FOR MILLING

Can you believe that Neodymium has enough pull force to hold down a piece of steel while it is milled? It can!

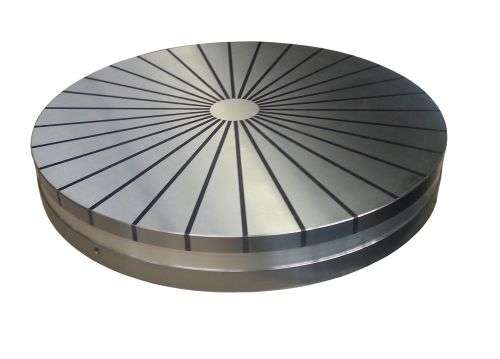

ID/OD ROUND PERMANENT MAGNETIC CHUCKS

The great thing about permanent technology is that there is no need for any power supplies. Turn the lever and get turning right away!

Where are the materials mined?

The materials used for permanent magnets, such as iron, cobalt, nickel, and rare-earth metals, are mined from various locations around the world. Here is some information about the mining sources for these materials:

1. Iron: Iron is one of the most abundant elements on Earth and is widely mined from deposits found in many countries. Major iron-producing countries include China, Australia, Brazil, India, Russia, and the United States.

2. Cobalt: Cobalt is primarily mined as a byproduct of copper or nickel mining. The Democratic Republic of Congo (DRC) is the largest producer of cobalt globally, followed by countries like Russia, Australia, and Canada.

3. Nickel: Nickel is mined from sulfide and laterite deposits. The largest nickel producers are Indonesia, the Philippines, Russia, New Caledonia, and Australia.

4. Neodymium: Neodymium is a rare-earth element and a crucial component in high-strength permanent magnets. The majority of neodymium production comes from China, which has significant rare-earth mineral resources. Other countries producing neodymium include the United States, Australia, and Myanmar.

5. Samarium-Cobalt: Samarium and cobalt are both rare-earth elements. Samarium-cobalt magnets are known for their high-temperature stability. These materials are primarily mined in China, as well as in smaller quantities from countries like Brazil, India, and Australia.

It’s important to note that mining operations for these materials can have environmental and social impacts, and efforts are being made to improve responsible sourcing practices and minimize negative effects.

FUN MAGNET HISTORY FACTS

Around the year 1000, a remarkable breakthrough unfolded – the discovery of magnets revolutionized the field of navigation. This pivotal moment was marked by the unearthing of natural magnetic rocks, specifically the iron-rich mineral known as magnétite. It was in the town of MAGNESIE, located in Minor Asia, where these magnetic rocks were first found.

The profound significance of this discovery cannot be understated. With the realization that iron could be magnetized using magnétite, a new era of navigation began to take shape. The development of the compass with a floating needle emerged as a remarkable advancement in the year 1200.

This is a momentous progression in navigation history!